Common Forklift Safety Hazards and Risks in Warehouse Operations

1. Bruises, Falls, and Crushing Injuries

When an accident occurs, lack of protective measures can lead to serious injuries, such as bruises, falls, or even crushing injuries, especially when drivers are ejected from their seats in a collision.

2. Collisions with People or Objects

Forklift operators often drive at excessive speeds or face unexpected situations where they don’t have enough time to react, resulting in collisions with pedestrians, goods, or warehouse equipment.

3. Forklift Overloading

Exceeding the forklift’s load capacity can cause it to become front-heavy or tip forward, creating a dangerous tipping hazard and increasing the likelihood of an accident.

4. Obstructed Visibility

When goods are loaded improperly, especially if they exceed shelf heights, operators may face restricted visibility, which can lead to collisions with people or objects while driving.

5. Blind Spot Collisions

Forklifts have inherent blind spots, which make it difficult for operators to see pedestrians or obstacles, resulting in dangerous accidents in high-traffic areas.

6. Lack of Reaction Time in High-Speed Maneuvers

Driving at high speeds or making sharp turns without sufficient reaction time can cause the forklift to lose control, leading to accidents with pedestrians or merchandise.

7. Lack of Operator Awareness of Surroundings

Forklift operators may become less aware of their surroundings in busy, cluttered environments, increasing the risk of accidentally hitting a person or object.

8. Insufficient Training or Fatigue

Operators who haven’t received adequate training or who are fatigued may misjudge distances, speeds, and obstacles, leading to unsafe maneuvering and accidents.

9. Unstable Loads

If loads are improperly secured, they can shift or fall off the forklift during movement, posing a significant safety risk to both the operator and nearby pedestrians.

10. Environmental Hazards

Uneven flooring, poor lighting, or narrow aisles can further complicate forklift operation, increasing the likelihood of accidents caused by loss of control or poor visibility

How Our Pedestrian Collision Avoidance System Can Enhance Your Warehouse Safety

We understand the critical need for safety in high-traffic warehouse environments. Our Pedestrian Collision Avoidance System is designed to protect both forklift operators and pedestrians by reducing the risk of accidents, ensuring a safer workplace for everyone.

Here’s how our system can make a difference:

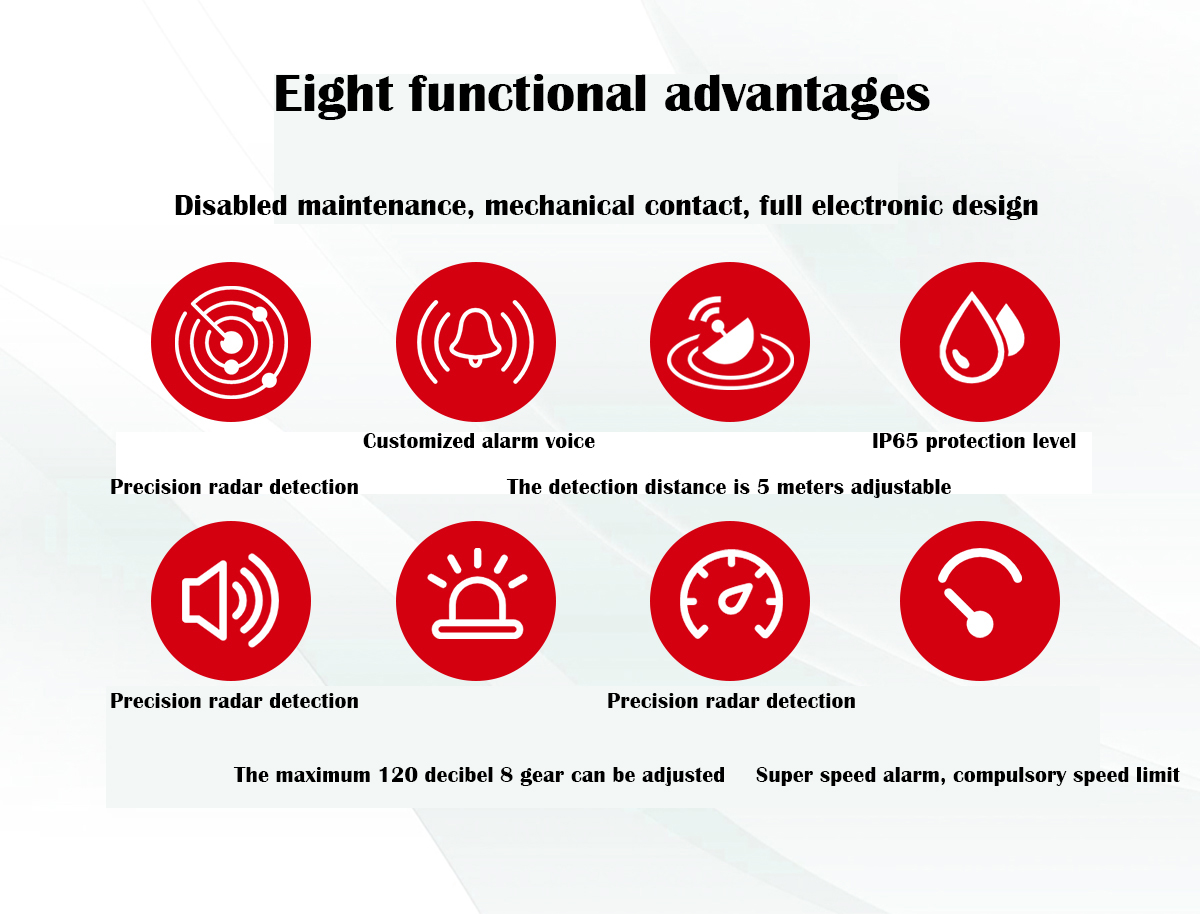

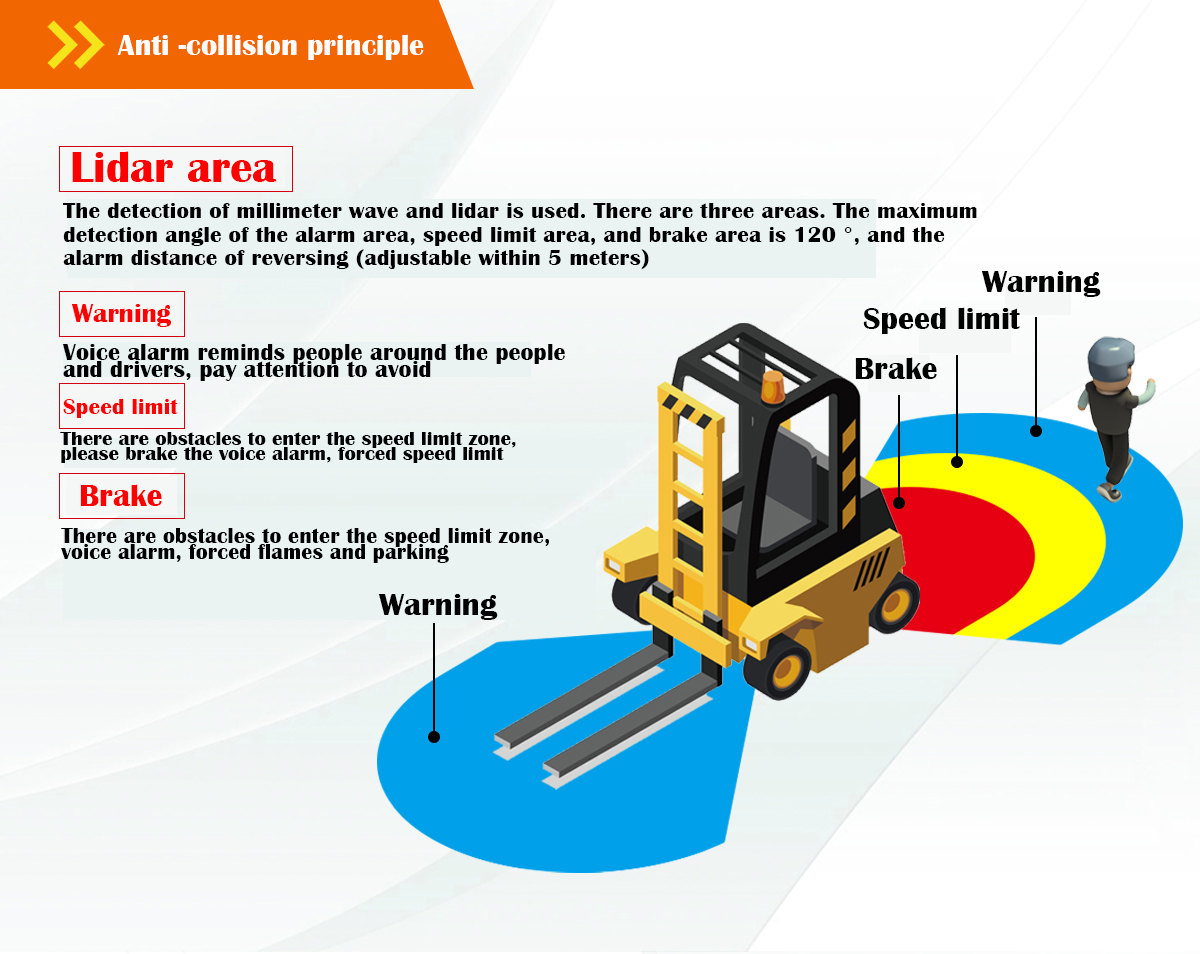

1. Enhanced Detection with 2 Millimeter radar Wave

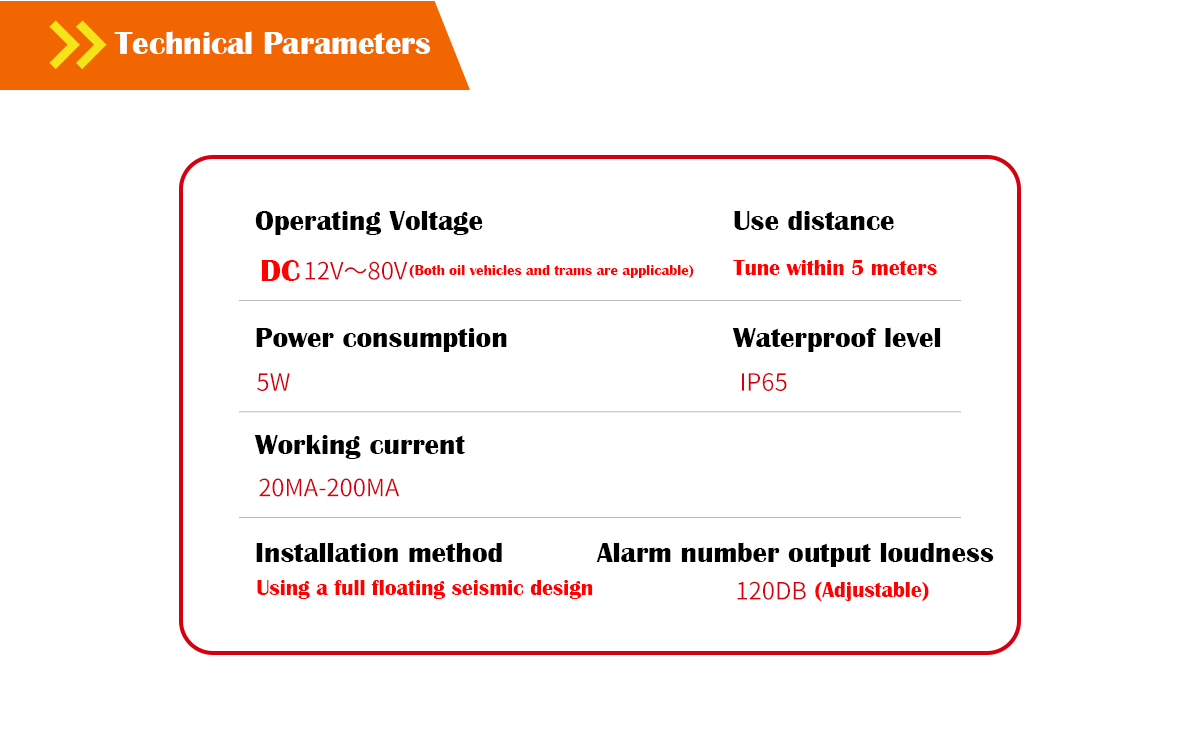

Our system uses advanced 2 Millimeter radar Wave technology, providing precise detection of pedestrians and obstacles within a 5-meter range. This ensures that forklifts are always aware of their surroundings, preventing dangerous collisions before they happen.

2. Multi-Function Alerts for Immediate Action

With anti-collision warnings, speeding alarms, and braking reminders, our system gives both the operator and pedestrians critical time to react. The system also offers optional speed limits and parking features to automatically adjust the forklift’s speed or stop it completely when a hazard is detected, keeping everyone safe.

3. Wide Voltage Range for Universal Compatibility

Operating at 12-80V, our system is compatible with both electric and oil-powered forklifts, making it suitable for a wide range of warehouse equipment. The simple installation process ensures that it can be quickly integrated into your existing fleet with minimal downtime.

4. Clear and Customizable Alarm Sounds

With a voice alarm that reaches up to 120 dB, the system’s warnings are loud and clear, even in noisy warehouse environments. The volume is adjustable, so it can be tailored to your needs, ensuring operators are always alerted to potential hazards.

5. Waterproof and Durable for Harsh Environments

Our system is built to withstand tough warehouse conditions with an IP65 waterproof rating, ensuring it continues to function optimally even in dusty, wet, or harsh environments.

6. Wireless Infrared Remote Control for Easy Management

For added convenience, the system comes with a wireless infrared remote control, allowing easy configuration and adjustments on-site, without the need for additional tools or technical expertise.

7. Comprehensive Support with One-Year Warranty

We back our system with a one-year after-sales warranty for peace of mind. Our team is ready to provide on-site service and technical support whenever you need it.

Wide Range Products Supply To Meet Your Solution

High Position Camera

The High Position Camera provides wireless magnetic mounting for easy installation, offering storage and recording capabilities for enhanced safety. With its portable power supply, this camera frees the operator from straining their neck while safely handling goods, improving visibility and ensuring smoother, more efficient forklift operations.

Seat Belt Alarm System

The Seat Belt Alarm System ensures compliance with safety standards by triggering a continuous alarm if the seat belt or life belt is not fastened. The system prevents the forklift from starting until the seat belt is securely fastened. Additionally, the system provides turning and reversing alarms for added safety during movement, helping to reduce the risk of accidents.

Forklift Speed Limiter

To address the risk of high-speed accidents, the Forklift Speed Limiter is designed to ensure safe operation by triggering audible and visual warnings when speed limits are exceeded. The system offers additional features such as reversing alarms, forced speed limits, and an optional forced stall function, ensuring forklifts operate within safe speed parameters at all times.

Forklift Permission System

The Forklift Permission System enhances security by requiring authorized personnel to operate the forklift. The system uses a real-name driver authorization process, ensuring that only authorized individuals can start the forklift by swiping their employee ID cards. This ensures accountability and reduces the risk of unauthorized operation.

Forklift Odometer

The Forklift Odometer offers precise tracking of forklift mileage and working hours, enabling fleet managers to monitor usage patterns and prevent forklifts from sitting idle. This system helps in optimizing resource allocation, improving operational efficiency, and ensuring better fleet management.

Blind Spot Monitoring System

The Blind Spot Monitoring System provides a 360-degree view of the forklift's surroundings, enhancing safety during operation. With reversing camera functionality and blind spot detection, the system includes pedestrian alarms and assists the driver with safer maneuvering, reducing the risk of collisions and improving overall operational safety.

The above is some or the product for the Forklift Pedestrian Collision Avoidance System, welcome to contact us to get your solution.

Troy

Troy